RAPID PROTOTYPING : 3D PRINTER

IGTR is instrumental in leading Gujarat industries to technology upgradation. Rapid growth of CNC technology in the area is due to them. Now they introduce Rapid Prototyping – RPT. The technology of tomorrow with RPT, one can indulge in product changes and have the prototype in hand next day morning. They have equipped ourselves with latest software for Product Design combined with RPT facility and finally latest of CAE software. All this for us. Now we can assure that our product meets all requirements before we go for high investment.

Now in India, Institutions like NID, IIT has RPT facilities and Industry also offers serviced in this area. But nobody has In-house Metal Rapid prototyping services. This process is introduced by Indo German Tool Room (IGTR), Ahmadabad in India. Since Franklin Kristi, who is voluntarily involved in design detailing process studied from IGTR and currently working with NID has taken up this project further for metal prototyping. Even IGTR has not done any commercial/research based work on this machine, and they were also curious to take this project as startup event. Hence, this was the first project of metal RP in its kind, we faced lots of difficulties from the initialstage. We had to convert the 3D model in to various formats to stick to our dimensional parameters. During the conversion the model deformed. This requires some more work on 3D model.

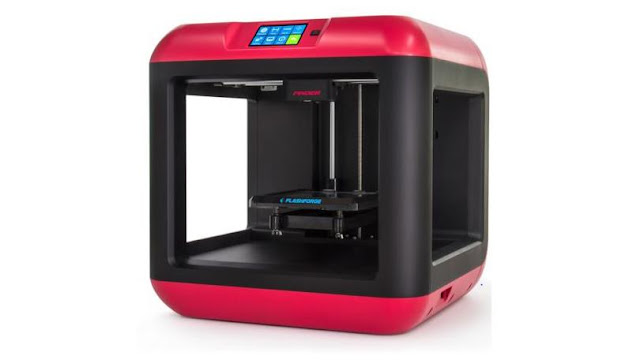

We tried making the first RPT, which unfortunately scaled down automatically by 50% by the machine. The component required 110 mm length and the output component was not having length more than 55mm. After the first attempt we went for the other try and this time we got the better output. Still we are not satisfied with the surface finish, IGTR also assured us to make one more prototype of same design once they work out the technical difficulties resolved. Specification of RPT at IGTR is as following.

Abbreviation : FDM Material type : Solid (Filaments) Materials : Thermoplastics such as ABS, and PC - ABS Max part size (LxWxH) : 355.6 mm (14.00”) x 254 mm (10.00”) x 254 mm (10.00”) Min feature size : 0.127 mm/ 0.005 in. Min layer thickness : 0.127 / 0.0050 in. Accuracy : 0 .127 mm / 0.0050 in. Build speed : Fast Applications : Form/fit testing, Functional testing, Rapid tooling patterns, Small detailed parts, Presentation models, High heat applications.

Now in India, Institutions like NID, IIT has RPT facilities and Industry also offers serviced in this area. But nobody has In-house Metal Rapid prototyping services. This process is introduced by Indo German Tool Room (IGTR), Ahmadabad in India. Since Franklin Kristi, who is voluntarily involved in design detailing process studied from IGTR and currently working with NID has taken up this project further for metal prototyping. Even IGTR has not done any commercial/research based work on this machine, and they were also curious to take this project as startup event. Hence, this was the first project of metal RP in its kind, we faced lots of difficulties from the initialstage. We had to convert the 3D model in to various formats to stick to our dimensional parameters. During the conversion the model deformed. This requires some more work on 3D model.

We tried making the first RPT, which unfortunately scaled down automatically by 50% by the machine. The component required 110 mm length and the output component was not having length more than 55mm. After the first attempt we went for the other try and this time we got the better output. Still we are not satisfied with the surface finish, IGTR also assured us to make one more prototype of same design once they work out the technical difficulties resolved. Specification of RPT at IGTR is as following.

Abbreviation : FDM Material type : Solid (Filaments) Materials : Thermoplastics such as ABS, and PC - ABS Max part size (LxWxH) : 355.6 mm (14.00”) x 254 mm (10.00”) x 254 mm (10.00”) Min feature size : 0.127 mm/ 0.005 in. Min layer thickness : 0.127 / 0.0050 in. Accuracy : 0 .127 mm / 0.0050 in. Build speed : Fast Applications : Form/fit testing, Functional testing, Rapid tooling patterns, Small detailed parts, Presentation models, High heat applications.

Comments

PP injection molding

Rapid Prototyping Service

Injection Molded Parts